If you are planning to install a beer dispensing system, then you are probably wondering how much such equipment will cost.

What Does the Draft Beer System Include?

Have you ever thought about how beer gets from the keg to your glass?

At first glance, it may seem like a fairly simple process. However, if you get a little bit into this, you will find that even the simplest system consists of several components that ensure its smooth operation.

The 3 most popular standard draft system options nowadays are a kegerator, remote glycol cooling system, and air-cooled beer system.

This question is difficult to answer definitively, as the final cost depends on many factors, from the selected equipment to the draft beer system installers, which will perform this work.

For more information keep reading our article.

All of these are quite similar: they work with almost the same draft beer equipment. But each system varies in the components involved in the process of beer dispensing and cooling.

1. Kegerator

Let’s start with the most common example of a draft beer system, which delivers this beverage from keg to beer tap.

If you’ve decided to buy a kegerator, consider that it works for a quite short distance. For example, when a keg is installed right under the bar counter.

Carbon dioxide or nitrogen is used to push beer from the keg through the beer line up to the beer tower and faucet.

The equipment includes the following components:

- Kegerator;

- Tank with CO2 or nitrogen with primary and secondary regulators;

- Air line to deliver gas from the tank to the draft system;

- Beer line that is attached directly to the keg coupler from one side and to the draft faucet from the other side;

- Stainless steel keg;

- Keg Coupler is used to connect the air line and the beer line to the keg;

- Shank is a chrome-plated brass tube with a thread pattern on the outside, that is used to connect the beer line with the faucet;

- Beer tower (a place where all the beer lines are located), faucet, tap handle, and drip tray.

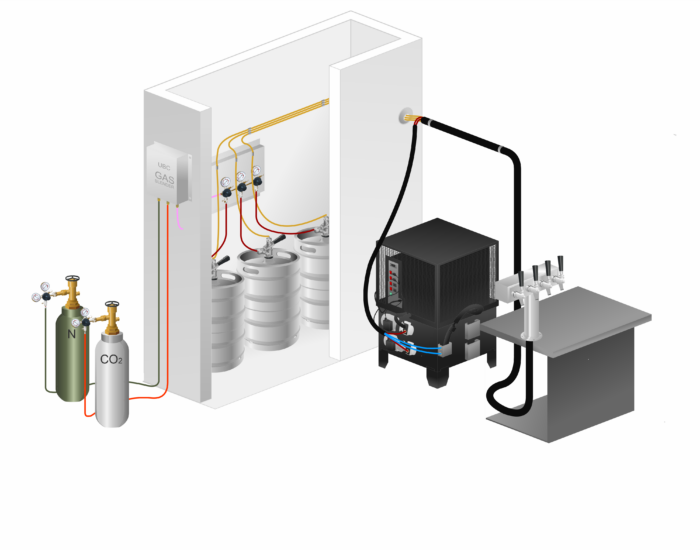

2. Glycol Cooled Draft System

If the kegs are situated far from the draft tower and faucets, then a Glycol Cooled Draft System is required.

This system keeps draft beer at a consistent temperature as it travels from keg to tap.

Such equipment allows to quickly cool the drink and maintains even the narrowest temperature ranges, up to +/- 1° (it works faster and more accurately than the Air Cooled Draft System).

In general, the system consists of the same components as a standard kegerator. However, there are some differences, such as Glycol Trunk Line and Glycol Chiller. They improve the antifreeze properties of the mixture and allow to achieve the necessary cooling.

3. Air Cooled Draft System

This is another long draw system that is used where the kegerator fails. Unlike the glycol system, air cooling is suitable for bars or pubs that have runs of less than 25 feet from keg to tap.

Air is blown through the duct to the draft tower for beer cooling.

Air Lines, Return Air Duct, Forced Air Blower and Chilled Air Duct are among the distinctive features of the system.

Draft Beer System Installation Process

- Start by planning the space for your future cooling system considering the keg dimensions.

- Prepare beer lines and tanks with carbon dioxide or nitrogen (depending on your needs, these tanks can be of different sizes).

- Drill 2 holes into the fridge to insert the beer lines. One line has to run from the CO2 tank to the keg, and another line from the keg to the beer tap.

- Take all the lines, couplers, and regulators and map out how everything will flow.

- Consider where the beer tap will be located. You can set it up at a bar or on the wall. Drill a hole and screw in the beer tap.

- Connect the regulator to the CO2 tank. It is screwed into the thread at the top. Connect the CO2 hose to the keg and secure it with a special clamp.

- Insert the coupler into the top of the keg, and secure the connection for optimal safety.

- Connect the CO2 line to the corresponding side of the coupler. And connect the beer line to the other side of the coupler. Again, make sure to secure all the connections.

- Place the hose from the fridge with the kegs to the bottom of the beer tap.

- Open up the CO2 (nitrogen) tank. Adjust the pressure, if needed. The pressure depends on the type of beer you are pouring. You can consult your local distributor on what the appropriate pressure for your brewery is. Consider that too low pressure makes the beer too foamy. And too high-pressure results in over-pressurized foamy beer.

- Test the system after the keg has cooled down enough. If all goes well, you can start the system for work.

- Everything is ready. Please yourself and your customers with a delicious fresh beer!

Cost to Install a Draft Beer System in Canada

The cost of draft beer system installation depends on several factors:

- Type of the system;

- Set of components for the system: additional equipment affects the price of installation;

- Draft beer system installers that will perform the work.

Pay particular attention to the last point: the reliability and efficiency of your draft beer system depend on it.

Here you can order:

- Installation and assembly of the kegerator

- Installation and assembly of the system with glycol, air, or instant cooling;

- Installation of direct and long draw systems;

- Installation of non-standard cooling units;

- Equipment Cleaning.

Representatives of the company will gladly calculate the cost of your order and will advise modern quality equipment for waste-free dispensing: kegerators and kegs, glycol chillers, beer towers, gas cylinders, main lines, drip trays, faucets, beer tap handles, etc.

The assortment of the brand also includes chillers for water, bar refrigerators, and much more for quality storage and serving of beverages.

It is staffed by experienced professionals whose level of service meets all industry standards, so you can be sure that all the equipment will work exactly as it is needed. They know how to install a modern brewery system so that your bar becomes even more popular among visitors!