Improve your production by taking full advantage of 3D scanning. Regardless of the size of your business and the industry to which it belongs, you can benefit greatly from the use of 3D scanners. Creating a 3D computer model faithfully represents and fully defines your idea. That way, you won’t spend a lot of time and money making changes before the final version.

It is an opportunity to find and develop different solutions before you decide on the final solution through prototype testing. You will also not risk making molds and tools used for mass production. For small batches and personalized products, 3D printing can be a better and more cost-effective solution.

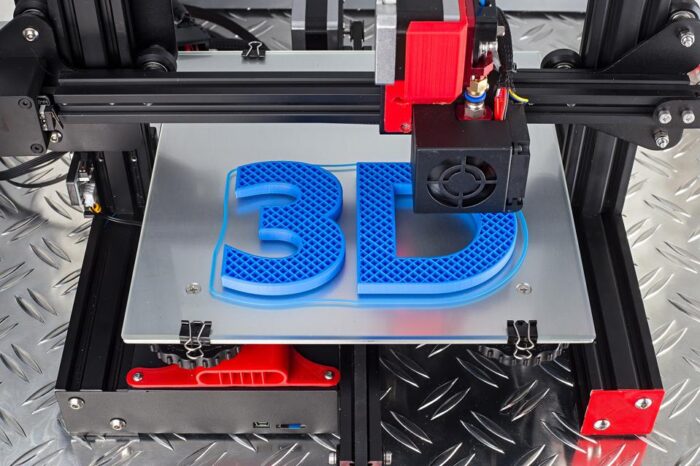

What is 3D printing?

It is an extremely fast and efficient solution. This approach differs from all other technologies in the preparation of the production process, because it is much cheaper and easier. The result of the application of 3D technology enables the creation of models, prototypes of different materials, and physical properties in a single process. In that case, models are created by applying several layers of material. According to the 3D-scantech the main advantages of 3D technology are better market research before investment, the printing of high-quality models, and a high percentage of flexibility.

This means that you will have a lot of possibilities when it comes to changing the conceptual design before the final production. If you decide on the right scanner or look for the services of a reliable company, you will get accurate and high-quality 3D modeling. The processing of images taken with a 3D scanner is done with sophisticated software tools. 3D technology is used in industrial car modification design, reverse engineering, furniture design, etc.

How much does it cost to 3D scan something?

Depending on the type of service you need and the nature of the product, you can pay $ 100 or more than $ 1,000. So, the price will depend on the size of the sculpture, design, and other things. One of the most influential factors is the complexity of the project. For example, a 3D fruit scan will generally take less than a day, while an expensive artwork scan will take much longer. This process can take days before satisfactory results are obtained. However, the 3D scan file will not always be ready to use. Sometimes you just don’t have enough good content to work with.

This is especially inconvenient if you want to do reverse engineering. In this case, certain parts of the model must be modified to obtain a smooth surface. It’s the job of a 3D sculpting expert or CAD designer to fix the file. The next hurdle that directly affects the price is items that are not impossible to scan. For example, it’s hair. It is also impossible to scan dark objects. Then the white powder is used which is easy to wash. Fortunately, this technology is getting better, which means that some of these problems will not exist in the near future or will become easier to deal with. The cost factor is also the equipment that comes with the scanner or the use of scanner services. Industrial 3D laser scanners cost over $ 20,000.

Object geometry

As you can read, several factors will shape the final cost of a scan, but we need to single out one. It’s about the geometry of the project. It is the primary factor that determines the price or the overall size of the project. The reason is very obvious – a larger object requires more scans compared to smaller objects.

Therefore, you can expect a higher price. It will also be easier to scan a flat surface compared to a complex surface. For example, surfaces that contain needles, columns, holes, and other features involve more work. The scanner will have to work longer to cover every feature and provide you with a detailed scan.

Different 3D technology

When choosing a 3D scanner, pay attention to detail. Since each model has its advantages and disadvantages, the choice of technology can determine the fate of your project. So focus on models that are compatible with the end goal. You need the right kind of technology for your task. The field of view is a critical aspect because you are not equally successful in handling objects of different sizes.

For example, large-frame objects require a scanner with a large field of view. This will make the whole process much more efficient. Otherwise, the scan will take much longer than necessary, and the price will be much higher than usual. Don’t forget that objects can be very small but also detailed while other objects can be large and open. Some objects may also be skeptical, which means you need dynamic referencing and high scanner speeds.

Application of 3D technology

Finally, we must mention the way technology is applied as another factor that has a big impact on the final price. Since it goes through a valuable process and through applications during 3D scanning, the way this technology is applied is of great importance. For example, if you need reverse engineering, you will probably choose to manually apply a 3D scanner to capture every detail of a component that is otherwise broken or damaged.

Regardless of the size of the project, the process is very meticulous and requires additional work. So thoroughly research the reputation of the scanning provider to make sure of its expertise. However, it is also important that you know what you want as an end result. This way you will have clear expectations and establish a quick and easy agreement with the provider.

Conclusion

Each production process consists of several key stages. The basis of the project is an idea and it all starts with her. It is enough to have a vision and a couple of drawings to develop a concept. However, it is even better to have a 3D printer that will materialize any idea in a very short time. 3D scanning saves you the time it would take to draw a particular model in one of the CAD programs.