Mechanics is a science that takes a long time to understand. Of course, this only applies to those people who have some basic knowledge, so it is a little harder for them to understand a science that is not related to them. While this science is quite understandable for those who deal with mechanics or robotics. Mechanics is actually the science of how to assemble something that will be functional, will help, and will not cause any downtime.

That is, this science simply deals with assembling parts that must function perfectly together into a whole, which will be functional without any defect appearing in the near future. Specifically, it is a matter of assembling a machine or system that will perform some function that will facilitate the operation of the human factor and will help in faster execution of duties. But is there a perfect machine? The answer is simple – yes, it exists, but it needs to be thought through and created in detail.

A perfect machine can exist, but in order for it to be great and easy to use and to have no problems, it needs to go through a detailed process of design by engineers, be contained in excellent and quality parts, and be tested. The tests best show what parts are used, if the parts are not good and if it does not work in sync, then the parts should be replaced with other better ones. As already mentioned parts are the most important part of a machine or robotic solution. The biggest role is played by those who are intended to move the machine or to move parts of it. So, as very important, we single out Linear Bushings. If you are not familiar with them and their use, we have good news for you! In addition, you will be able to find out everything about them, it is only up to you to sit comfortably and read us to the end.

What are Linear Bushings?

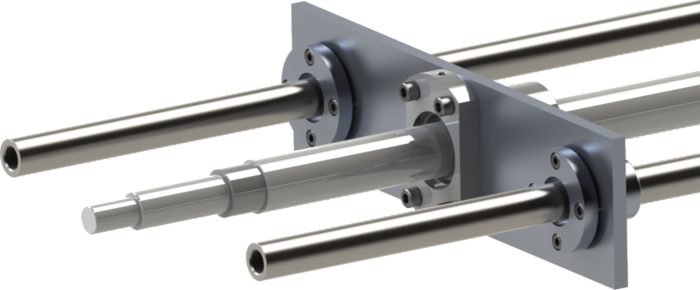

We are sure that you have seen one of us machines that make linear movements to deliver something in short distances in the factories, and we are even more sure that you have seen what linear movements 3D printers make. If you have seen this, you need to know that Linear Bushings are responsible for those movements. They are a kind of couplings that with the help of their mechanism move on a straight surface, usually thin and smooth rods.

By moving along the bars, they follow a straight path according to the need of the machine itself that contains this mechanism. You need to know that without them the line system is incomplete and that a good and quality line system requires quality joints and smooth bars. This is important so that they work great and synchronized together, and if you need advice on quality parts or you need great bushings or bars in that case visit tuli-shop.com and get advice or ask for everything you need. This way you will have quality parts that will later give you a perfect and functional product.

What materials are used to make quality Linear Bushings?

As already mentioned above, to make a quality machine system or robotic final solution, the parts need to be made with quality. We are witnessing a different time than before. We live in a time of a huge market economy where supply and demand meet in the markets. There is too much competition for all types of products, and there is too much competition for these products even though they are not very attractive to buyers. So you can find the most diverse designs of Linear Bushings which are made with many errors, wrong and inaccurate dimensions, and from bad materials.

When you are looking for quality parts like this, in that case you have to look for such products which are made of quality aluminum and excellent metal-polymer. If these two ingredients are in the part that you have been measuring for a long time, then you can be calm because the composition is quality. Another thing to look out for is the places you buy from. See it as companies with a great portfolio, good collaborations, and a small percentage of mistakes and failures. This will make sure that you have a great product that you can insert into your machine or robotic solution.

What are Linear Bushings Used for?

We have already talked about the composition of these accessories in the assembly of the machine with which it works, and now we will talk about what they serve. Linear Bushings are something without which the Linear-motion bearing system would not work. It is a whole system that cannot function without these add-ons. They are mounted on rods made of concentrated aluminum and move on them with the help of pressure created by the machine itself or a robotic solution.

We can usually see them on 3D printers where they move the system that shapes the figure of plastic consumables. So you can use these Linear Bushings to move in your machine solutions, robotic solutions, but they are also used as replacement parts for 3D printers. These pieces are the gold of mechanics without which mechanics can not. Keep them in mind if they can fulfill any of the uses listed above.

Never forget one thing!

The only thing you have to pay attention to when using these pieces, but also on all machines or robots in general is to perform regular inspections and regular service. This will save you a lot of money on repair costs, but it will also save you time on repairing and servicing the mechanism. Pay attention and check-in time to protect the process in which these parts help you.

Now that you are familiar with the use, benefits, and everything else related to these mechanical parts, you are ready to work on the new innovative solution that will help you with Linear Bushings and make your work and operation easier. Make sure you buy only from quality manufacturers and buy products made of quality ingredients so as not to lead to higher costs and other adverse situations. Be the innovator of the new age using such wonderful and functional possibilities offered by Linear Bushings and mechanics.