Autonomous Mobile Robots (AMRs) are state-of-the-art industrial robots that can offer high-end logistics support on an industrial or commercial level. Material handling and internal transportation take up a significant share of industrial operations. And using the right kind of AMR from MiR can help you optimize the workflow of your shop floor, production plant, or retail store.

Businesses or production units of any size can implement the use of AMRs and get a higher degree of efficiency. It is even ideal for small and medium-sized businesses as it brings in a cost-effective solution to all their internal transportation and logistics requirements.

Mobile industrial robots are apt for transporting raw materials and finished goods between warehouses, production plants, work stations, laboratories, and many more departments of the internal supply chain to achieve higher efficiency.

Types Of Autonomous Mobile Robots You Can Utilize

Autonomous Mobile Robots offer the most advanced collaborative services in terms of load volume and shop floor efficiency. You can use any of the below-mentioned AMRs and meet the requirements of your industry and achieve logistical success in both production plants and supply chain management of the finished goods.

MiR100

It offers a safe and cost-effective solution for smaller load transportation requirements. It can be easily programmed to the desired transportation requirements and movement around the obstacle.

MiR250

This Autonomous Mobile Robot is more agile and offers higher efficiency with a payload of up to 250 kg. It has a smaller footprint, great adaptability, flexibility, and optimized internal transportation support.

MiR Hook 250

This AMR is an ideal choice for different kinds of towing jobs around the shop floor and industrial warehouse.

MiR600

This AMR offers higher efficiency and can withstand liquids and dust particles. It is a robust, flexible, and reliable option to carry goods in an industrial environment.

MiR1350

This AMR has a robust structure and is a great choice for moving around a very high payload. It has great serviceability and a longer lifespan.

MiR EU Pallet Lift 1350

This AMR can autonomously collect, lift, and carry pallets to deliver them o the designated area in an industrial environment. It offers stable handling and higher efficiency.

Whether you require to transport smaller loads or heavy loads, you can very much use some of the Autonomous Mobile Robots for repeat movements and continuous actions. You can free up your manpower from such monotonous and laborious tasks and utilize their full capabilities for some more important tasks.

Which Industries Can Use AMRs

Autonomous Mobile Robots are good for carrying various kinds of loads at job sites as they bring in a lot of efficiency on the floor. You can utilize them in various industries to carry goods and products from one location to another. Here is a list of industries that can largely get benefited from the use of AMRs.

Healthcare Sector

The healthcare sector, including hospitals, need efficiency more than ever before. You can use Autonomous Mobile Robots for carrying out non-value-added tasks like moving medicines, pharmacy products, and test reports from one place to another.

You can also use AMRs for pushing carts with used or clean hospital linen and waste bins, transporting meals for patients from the kitchen to the ward, and return back the empty trays.

The use of Autonomous Mobile Robots will leave the hospital staff with extra time and space that they can use on more value-added tasks and ensure higher efficiency of the hospital.

Electronics Industry

The electronics industry has seen excessive growth in the last couple of decades. It is especially because of the dependency of people on different kinds of electronic goods. The demand for consumer electronic goods is extremely high as consumers today expect more durable, high-quality, and sustainable products in every product they use.

You can automate a shop floor by incorporating Autonomous Mobile Robots and ensure a super-productive, flexible, and optimal supply chain of the manufactured goods.

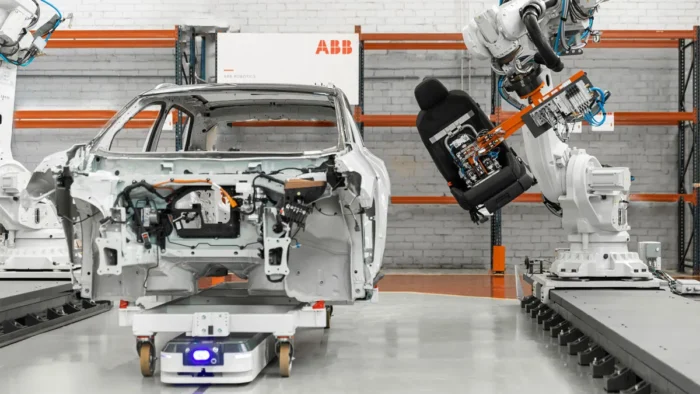

Automotive Industry

The automotive industry can gain a lot by optimizing its shop floor with Autonomous Mobile Robots. Carrying products from one corner to another becomes rather easy and convenient with use the of AMRs as they are quite easy to set up.

They do not need any fixed routes to function and can move away from any obstacles and maintain their onward journey to reach the assigned destination conveniently.

Autonomous Mobile Robots require very less monitoring as they are quite self-efficient and can function optimally.

Life Science Industry

The life sciences industry comprises pharmaceuticals, biotechnology, medical technology, and nutraceuticals industries. And this industry functions on a very high level of performance to keep up with the pace of demand and supply.

The use of Autonomous Mobile Robots can help such industries bring in efficiency, increase productivity, incorporate flexibility, and finally offer an increased ROI. You can improve the plant workflow with optimum goods transportation and plant management.

Logistics & 3PL

The logistics & 3PL industry has seen rapid growth in the past few years, especially for the boom in ecommerce sales and customers’ expectations to receive their goods on time. Incorporating Autonomous Mobile Robots on the shop floor can accelerate work efficiency as a whole.

Utilizing AMRs for internal logistics and 3PL services is a great way to bring in efficiency and timely completion of designated work. Using AMRs can be a very cost-effective solution in comparison to utilizing a large number of manual laborers on the floor.

Fast Moving Consumer Goods (FMCG)

The FMCG industry is ever-growing, which brings a high expectation on the goods manufacturing companies to meet customers’ demands. The use of technology and process automation has become a must for these companies to keep up with the global demand.

And here comes the requirements of using Autonomous Mobile Robots and optimizing production plant activities. AMRs are adaptable to the growing demand of the industrial floor, and they are east-to-use while ensuring higher efficiency.

The Bottom Line

The deployment of Autonomous Mobile Robots has become an essential aspect of businesses of all sizes and volumes. AMRs are easy-to-deploy and offer a cost-effective solution to process automation along with offering higher efficiency. AMRs are flexible, efficient, and safe to use in any industrial plant or shop floor.

If you want more information on AMRs, read here.