Product movement through different phases of manufacturing, packaging, and distribution is largely dependent on effective conveyance systems in the liquid sector. This article explores the many types utilized in the beverage business, emphasizing their advantages, disadvantages, and uses.

Introduction to Conveyance Systems in the Beverage Industry

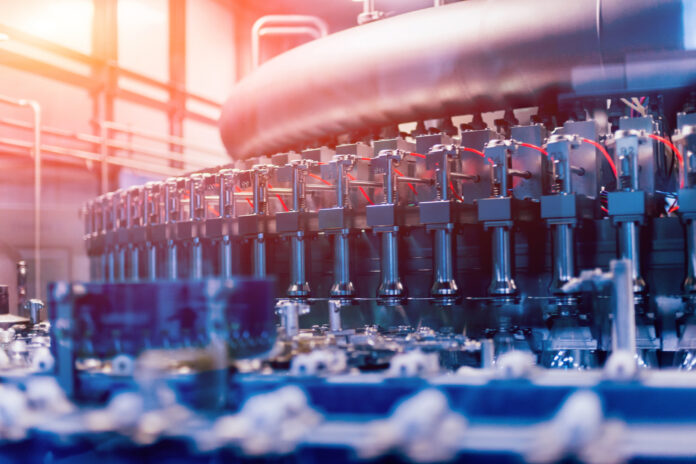

A critical component of the business is conveyance systems. They are in charge of ensuring that containers, completed goods, and raw materials are transported smoothly. Ensuring effective, secure, and sanitary transportation within the institution is the main objective. The significance of preserving production flow and quality control is discussed in this section.

Types

The beverage industry employs various types of conveyance systems, each designed for specific tasks and product types. Common systems include belt conveyors, roller conveyors, pneumatic conveyors, and chain conveyors. Each one of them has unique features that make it suitable for different stages of the production process. This section provides an overview, of their applications, and selection criteria.

Belt Conveyors in the Beverage Industry

Belt conveyors are among the most widely used conveyance systems in the beverage industry. They consist of a continuous belt that moves over rollers or a flat surface. Belt conveyors are ideal for transporting a wide range of products, from bottles and cans to cartons. Their versatility and efficiency make them a popular choice. This section highlights how belt conveyors function and their benefits in the liquid industry.

Challenges and Solutions

Despite their advantages, belt conveyors face challenges such as maintenance, product spillage, and contamination risks. Regular maintenance is essential to ensure longevity and proper functioning. Implementing spillage control measures and ensuring hygienic conditions are also critical for maintaining product quality. This section discusses these challenges and potential solutions to optimize belt conveyor systems.

Roller Conveyors in the Beverage Industry

Roller conveyors are essential for handling containers and packaging in the beverage industry. They consist of rollers mounted in a frame, allowing products to move smoothly over them. Roller conveyors are particularly useful for heavy or irregularly shaped products. Their simplicity and durability make them an attractive option for many manufacturing facilities. This section examines the functionality and advantages of roller conveyors in the industry.

Challenges and Solutions

The primary challenges with roller conveyors include alignment issues, noise, and wear and tear. Proper installation and regular maintenance are crucial to prevent misalignment and reduce noise levels. Additionally, selecting the right type of rollers and bearings can extend the life of the conveyor. This section addresses these challenges and provides practical solutions for the effective use of roller conveyors.

Pneumatic Conveyors

Materials are moved through a pipeline by pneumatic conveyors using vacuum or air pressure. When it comes to transporting grains, powders, or tiny particles utilized in the manufacturing process, they are very efficient. Their closed system lowers the chance of infection and guarantees excellent cleanliness. The benefits of pneumatic conveyors in the beverage sector are examined in this section along with their operation theory.

Pneumatic conveyors can be energy-intensive and require careful design to minimize product damage. The key to overcoming these challenges is in the design and optimization, including the proper selection of air movers, filters, and receivers. This section discusses these challenges and outlines strategies for optimizing pneumatic conveyor systems in production.

Chain Conveyors

Chain conveyors are robust systems used for moving heavy loads, such as pallets or large containers, in the beverage industry. They consist of a series of connected links or chains that move along tracks. Their strength and durability make them ideal for heavy-duty applications. This section delves into the functionality and advantages of chain conveyors, emphasizing their role in heavy-load transportation.

Automation and Integration

Automation in conveyance systems introduces a new level of efficiency and accuracy in the beverage industry. Automated conveyors equipped with sensors and control systems can adjust their speed, monitor product flow, and reduce manual intervention. This integration results in a more streamlined production process, minimizing human error and maximizing throughput. This section will focus on how automation transforms traditional conveyance methods, leading to increased productivity and cost savings.

Integrating automated conveyance systems with existing production lines can present challenges, including compatibility issues and the need for skilled personnel. Advanced technological solutions, such as programmable logic controllers (PLCs) and customized software, can help overcome these hurdles. This section will discuss the importance of choosing the right technology for integration and the role of skilled professionals in managing these advanced systems.

Sustainability and Environmental Considerations

Sustainability is becoming increasingly important in the beverage industry, and it plays a significant role in this regard. Energy-efficient conveyors, use of renewable energy sources, and reduction of waste are key factors in promoting sustainability. This section will explore how adopting eco-friendly practices not only benefits the environment but also leads to long-term cost savings and improved brand image.

While the move towards sustainability is critical, it comes with challenges such as higher initial investment and the need for ongoing innovation. Companies are developing new materials and technologies to make them more environmentally friendly. This section will discuss these challenges and the latest innovations in sustainable conveyance solutions, such as solar-powered conveyors and recyclable materials.

Safety and Compliance

Safety is paramount in the drink industry, particularly when it comes to conveyance systems. Ensuring worker safety involves designing conveyors with protective guards, emergency stops, and safe access points. This section will cover the essential safety features and how they protect workers while maintaining efficient operations.

Compliance with industry standards and regulations is crucial for beverage companies. This involves adhering to food safety standards, workplace safety regulations, and environmental guidelines. This section will delve into the importance of design and operation, highlighting the role of regular audits and certifications in maintaining industry standards.

Conclusion

The foundation of the beverage business, conveyor systems are essential to preserving both product quality and manufacturing efficiency. It is easier to choose the appropriate conveyance system for each step of the beverage manufacturing process when one is aware of the many types available and their particular uses. Despite some obstacles, they may be optimized with good administration and upkeep, guaranteeing seamless and productive operations in the beverage sector.