To get everything we need from any category, there needs to be a way to create it. Especially when it comes to production, which is very important. Production is important to be organized in a specific way, that is, it is necessary to organize the processes and of course, the machines, even for the smallest small parts or iron works that require specific equipment or a machine, and one such machine is Punch and die.

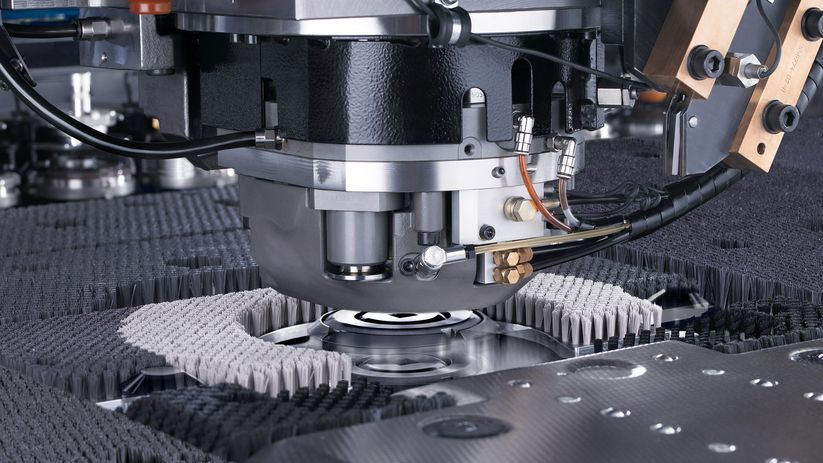

A machine with the help of which a large part of the parts or the small iron accessories that are needed are obtained. Punch and dies are machines that cut metal parts into specific shapes. They are commonly used in manufacturing industries such as automotive, aerospace, electronics, and medical equipment, hence the need for all these machines of this type.

Punch and dies are mechanical devices that operate using a combination of force and pressure, which is needed to get everything that is needed in the industry. That principle of making allows one to get what is needed to produce or create something in the industry.

The machine uses a punch to push metal through a die, which cuts the material into the desired shape, and thus gets every part that is needed in the industry for the preparation of medical equipment, cars, airplanes, machinery, and everything else. This machine is the key to everything that is needed in terms of parts and accessories in the further part of the assembly and preparation of these large products and objects.

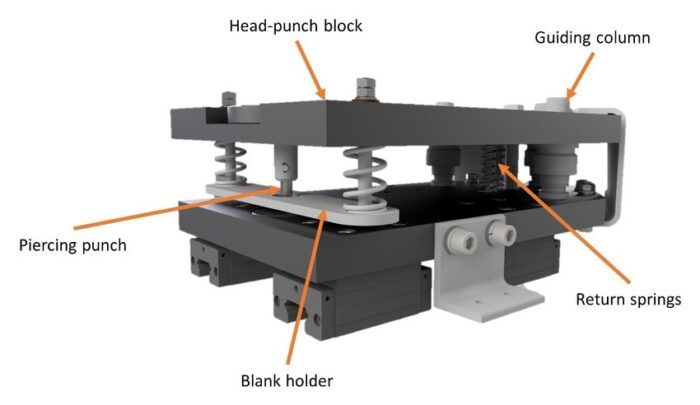

A punch and die system consists of two main components: a punch and a die. The punch pushes the metal through the die, which cuts the part into its final shape. However, the machine must be used correctly, it must be from a quality manufacturer of die punching machines that can provide what is needed by the company that needs it. And do you need such a machine for your business, but you don’t know how it works?

Today we will make sure to make things much clearer for you by explaining how the machine works and the whole process around it. You can learn more about that in the continuation of today’s article. Let’s get started!

1. Punching & Dies – what do you need to know about the machine?

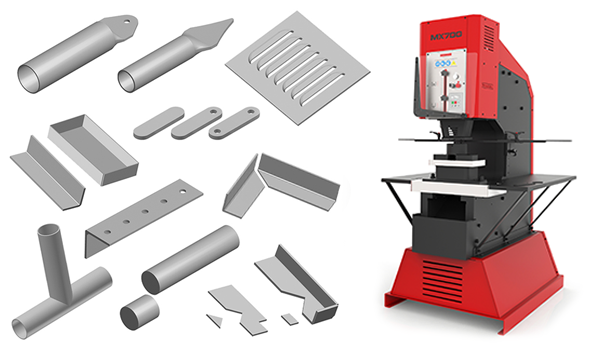

Each of the tools used in the production process has its own purpose, and the machine called Punch and die has such a purpose. Punching & dies are machine tools used to cut sheet metal, plastic, or wood in the shapes that are needed in the production process.

Each of the companies that manufacture something specifies what it is that they will produce, from which material, and then according to their needs, they look for such a machine that will do all the necessary things, that is, it will facilitate the production process.

Typically, these tools use a hardened steel point against a softer material (metal, plastic, etc). When they strike the harder surface, they create a chip out of the soft material and then move back towards the operator.

The work process is very simple and as we said they are very useful, so if you need such a machine it is important to do your research in time, see what is the best solution for you in terms of quality and buy the best one.

2. Types of Punches & Dies

As with any type of machine used in production, there are different types of these machines that are adapted to the needs of manufacturers. There are three basic types of punches & dies, each depending on how the tool is used. Let’s see together who they are and how they would help you.

- Rake Style Punches & Dies – These tools have a wide flat face that helps push debris away while cutting.

- Straight Edge Punches & Dies – Have a sharp edge on both sides of the punching action.

- Round Face Punches & Dies — Have a rounded face that creates a circular shape on the object being punched.

Each type has its own advantages and disadvantages, which is normal for any device that is used in production, so according to what you need, you will take these advantages and disadvantages into account and choose the best one for you.

For example, Rake-style tools are great at pushing debris away from the area being cut, but can’t reach corners, holes, and/or edges which some manufacturers need, but some don’t need in the production process.

Straight edge tools can access any spot on the item being punched, but don’t do much for pushing debris away, and are good for straight cuts. This is an advantage for some and would come in handy in production, but for some, it is a weakness, so they will avoid it as an option.

Round face tools are great at accessing any corner, hole, or edge, but are terrible at pushing away the debris created while cutting, also a weakness for some manufacturers, but it is still necessary to perceive, research and choose the perfect thing which will bring stable and constant production with the help of such machines.

3. Punch Size & Shape

When talking about punching size, we’re generally referring to the diameter of the tip. Bigger numbers mean bigger tips. Smaller numbers mean smaller tips. Thus, it is necessary to perceive and see what types you need and accordingly choose the necessary equipment and determine the specifications that the machine should have.

The shape refers to the shape of the tip. Many people think the bigger the number, the sharper the edge. That’s not true. In reality, the larger the number, it means the wider the tip, so now you know this and you can guide yourself in the further process of choosing and using this type of machine.

In front of you are a number of details and information that you probably did not know, but now that you know them, they would help you much more easily see the need for using the punch and die machines, and thus get what you want you to need it in your production facilities. Be careful and choose the one that will be most useful to you, and it needs to be a quality machine with excellent features.