Every metal manufacturing industry has come across the extrusion process. The process is nothing but a heated metal will be enclosed in a cavity and it is forced through the die opening where it will take the shape of the profile. Extrusion is one of the efficient and cost-effective methods.

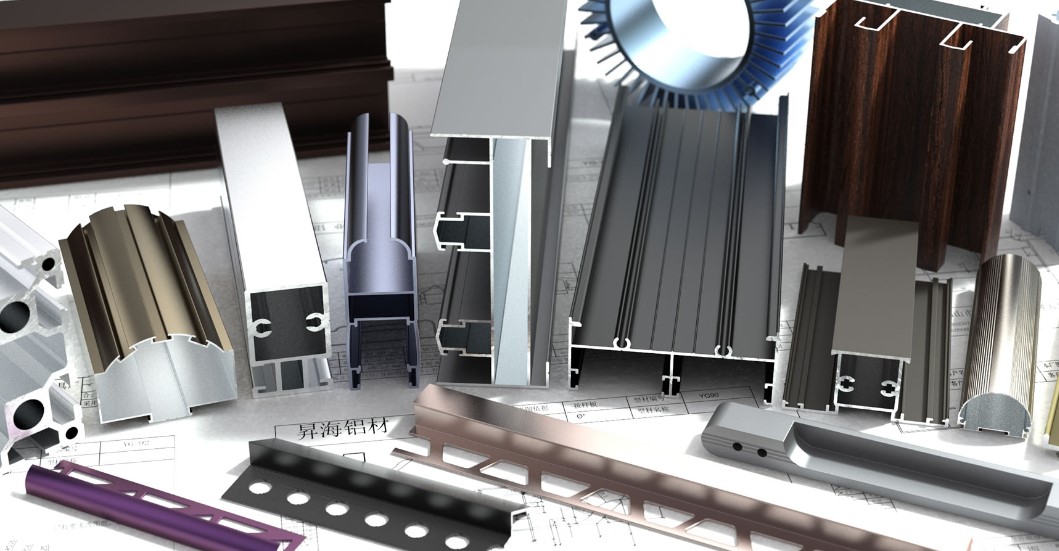

In comparison with other metals, extruded aluminum shows greater strength and better performance. Custom aluminum extrusions can be used for a wider range of applications, and it has a lot of benefits.

Know the benefit of custom aluminum extrusions

Custom aluminum extrusions are the most recommended product for the manufacturers as they will get transformed to the desired shape and size easily. During the extrusion process, it will make sure to enhance the strength of aluminum, and also the finished products will be much more durable and reliable than the natural ones.

The major advantage of extruded aluminum is it can be changed as per people’s needs, it is cost-effective, has less waste of material, and also saves your money. Find out the reasons why custom aluminum extrusions are most preferred;

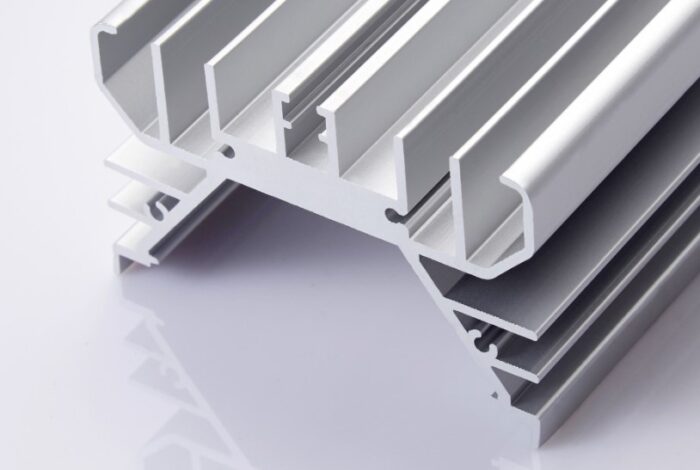

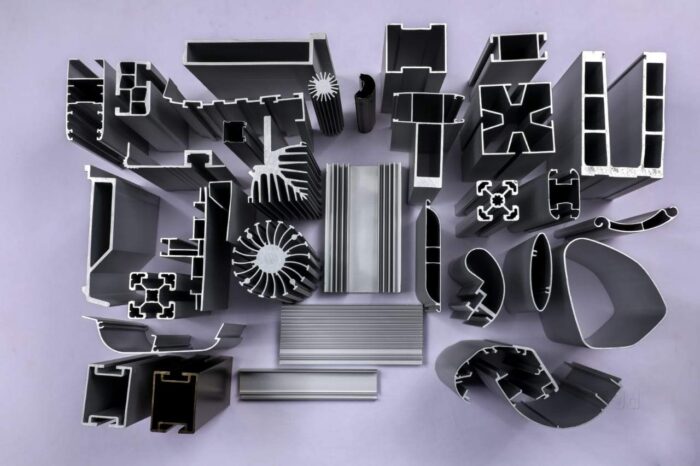

- Good at creating complex cross-sectional shapes

- Produced with a wide range of aluminum alloy grades of different mechanical properties

- Can be shaped with close tolerance as per your needs

- Can be coated with all kinds of finishes

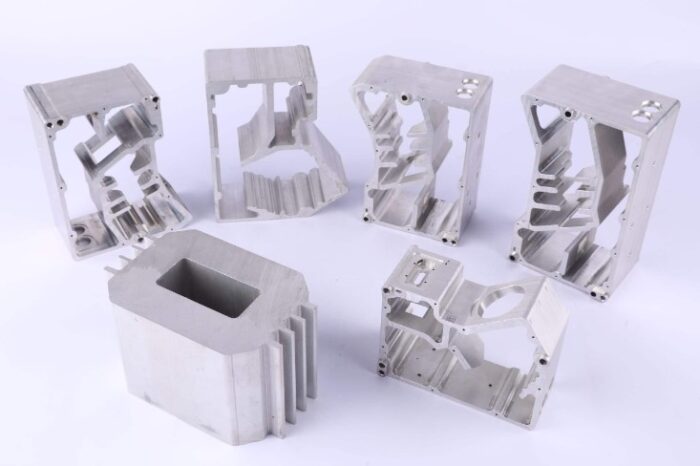

- Can be machined and fabricated with holes and markings for final use

How custom aluminum extrusion products are processed?

When it comes to the manufacturing process, the design of the custom aluminum extrusions can be complicated, but the process involves simple and easy steps. Aluminum is one of the most recycled materials on the planet, as it can be recycled and reused easily.

Here are the processes on how to manufacture custom aluminum extrusions

Get the starting material

The extrusions process mostly uses billets made from 99.9% recyclable aluminum or other types of aluminum, and the billets are cut in small lengths to avoid scrap metal. Depending on the weight and length of the customized aluminum extrusion, the billet can be cut.

Heating process

In an oven, the billets will be heated to the proper temperature, and make sure it is at the proper temperature so the extrusion process will be better. Then, the heated material is pushed through the steel profile or die and the aluminum will flow out with the exact same shape as the profile. After this, the extruded aluminum will follow the cooling process. Also, depending on the length, to make a larger size the extruded aluminum can be stretched.

Customize the final product

After the stretching process, the extruded aluminum is cut as per the customized size, and it will be heat treated so that the aluminum will get hardened to the maximum capacity. The main aim of the extrusion process is to make aluminum more beneficial than it was in its natural state. When the aluminum is made by the extrusion process, the properties of the extruded aluminum will be increased.

Benefits

Eco-friendly

The custom aluminum extrusions are considered eco-friendly products when it comes to the emission of greenhouse gases and the consumption of energy. Also, when compared to the other metals, aluminum is the only metal that can be recycled and reused easily, without disturbing its physical properties. The best part is the recycling process of aluminum also consumes a fraction of energy.

Cost-effective

Aluminum is a cost-effective product as it is easy to work with so it will reduce the cost of other tooling procedures. If you are looking for a material that can work under a tight budget then aluminum extrusion is the one to consider. The custom coating solutions on alumina can be easily done at the fabrication stage, and it includes painting, powder coating, and anodizing.

High precision

One of the biggest advantages of custom aluminum extrusions is the capacity to the “close tolerance”. There are extrusion supplies that are used to make complex shapes and sizes, and all the materials will come with precise specifications. Most customers love to have high-precision products and aluminum has the capacity to accommodate all these requirements.

Versatile design

The aluminum can be extruded as per the customer demands, and depending on the specifications you will get the aluminum. Even you will get additional customization that will enhance the look and feel of the product.

Better performance

Custom extrusion aluminum is widely used for various applications, and it is a non-magnetic and a good conductor of electricity and heat. The extrusion of aluminum is strong and durable, and it is anti-corrosive, so an excellent option for outdoor applications.

Applications

- Aluminum extrusion is used in the transportation industry so it is ideal for engine blocks, transition housings, roof rails, boats, trucks, railways, and other components of the vehicle. It is mainly used as the structural component in the manufacture of lighter automobiles

- Aluminum conducts heat efficiently, so it is used in automobile reactors and air conditioners, and also in the heating and cooling devices of computer

- The main advantage of aluminum is it offers natural rust and corrosion resistance without going through any additional treatment. This is because the aluminum has a thin and naturally occurring protective element on the surface which is aluminum oxide

- The extruded aluminum tube can be used as coaxial cables and wires, as it is non-magnetic. This is used for high-voltage applications and any kind of application where the magnetic field is present or a sensitive magnetic field is used

- It is also used in the construction industry as aluminum resists distortion which is caused by the weather and building movement. It offers high strength and flexibility under heavy load, and springs back to the normal position from the shock of impact

- The aluminum shows a high characteristic of reflection so it can be used for shielding products or you can use them in areas from light, radio waves, and infrared radiation