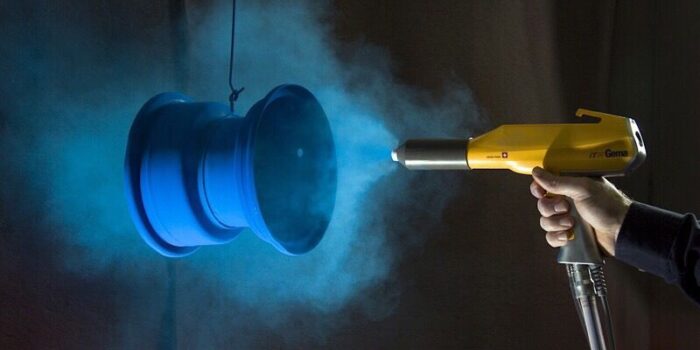

Powder coating is a highly effective finishing process widely used in various industries, from automotive to architecture. Unlike traditional painting, which involves liquid coatings, powder coating uses electrostatically charged dry powder particles. This process offers numerous benefits, including durability, resistance to chipping, scratching, and fading, as well as a wide range of color options.

The versatility extends to metals, plastics, and even wood, making it a popular choice for both functional and aesthetic purposes. As we delve into the world of powder coating, let’s explore the different finishes available and the key factors to consider when choosing the right one for your project.

Understanding Different Powder Coating Finishes

When considering powder coating finishes, you’ll find them broadly categorized into two main types: thermosetting and thermoplastic. The thermosetting finishes are known for their durability, as they undergo a chemical reaction during the baking process, resulting in a tough and permanent coating. On the other hand, the thermoplastic finishes offer a unique advantage – even after curing, they remain malleable, allowing for potential reflow and rework.

Within these categories, a plethora of finishes awaits, including matte, gloss, metallic, and textured options. Each finish imparts its distinct appearance and performance characteristics, making it easier for you to tailor the layer to your specific project requirements, be it an architectural masterpiece or a simple application like powder coating Las Vegas.

Factors to Consider Before Choosing a Finish

Before selecting a finish, several crucial factors must be considered. The intended application and the environmental conditions the coated object will face are essential considerations. High-traffic or outdoor items, for example, require finishes with enhanced weather resistance. Additionally, the level of desired protection against corrosion, chemicals, and UV rays should guide your decision. Budget constraints, color preferences, and the aesthetic appeal you wish to achieve should also play a role in your choice. Balancing these factors will ensure you select a finish that meets both your functional and visual needs.

The Role of Color and Texture in Coating Selection

Color and texture are significant contributors to the overall aesthetics of any coated object. It offers an extensive palette of colors, including standard, metallic, and custom shades. Customization is particularly valuable when branding or design specifications must be met. Texture options range from smooth to wrinkled or even hammerstone, enabling you to achieve the desired look and feel of your project. Consider the interplay between color and texture to evoke specific emotions or match the visual ambiance of your surroundings.

Exploring Popular Powder Coating Types: Pros and Cons

Different types cater to specific requirements, and understanding their pros and cons is essential in making an informed decision. Epoxy-based powder coatings offer excellent adhesion and chemical resistance, but they may not withstand prolonged UV exposure. Polyester-based powders, on the other hand, exhibit superior UV resistance and color retention. Hybrid powders combine the best qualities of epoxy and polyester layers, providing enhanced durability and flexibility. Each type has its strengths and weaknesses, so evaluating their characteristics against your project’s needs is crucial.

Specialized Finishes for Specific Project Requirements

Certain projects require specialized powder coatings to meet specific demands. For instance, heat-resistant coatings are ideal for applications in high-temperature environments, like exhaust systems and industrial ovens. Anti-graffiti layers provide easy cleanup for public spaces, while antimicrobial finishes are essential for healthcare facilities and food processing areas. There are also low-cure or UV-curable powder coatings, which reduce energy consumption during curing, making them environmentally friendly and cost-effective options.

Environmental Impact and Sustainability

Environmental impact and sustainability are critical considerations in today’s world. As we face mounting challenges from climate change and resource depletion, it is imperative to adopt eco-friendly practices in all aspects of life. Industries must prioritize sustainable processes to minimize their carbon footprint and preserve natural resources. From manufacturing to energy production, responsible choices can significantly reduce environmental harm.

Recycling, reusing, and reducing waste are essential strategies for promoting sustainability. Embracing renewable energy sources and employing greener technologies are vital steps toward a cleaner future. Individuals, businesses, and governments must collaborate to protect our planet and ensure a sustainable environment for generations to come. By making conscious choices and taking decisive action, we can create a greener and more sustainable world.

Preparing Surfaces for Optimal Coating Adhesion

Achieving a durable and flawless finish begins with surface preparation. Proper cleaning, degreasing, and removal of any contaminants are vital to ensure optimal adhesion. Surface profiling techniques, such as sandblasting or chemical etching, enhance adhesion for improved longevity. Following the correct surface preparation protocols not only ensures a successful coating but also minimizes the risk of premature failure due to poor adhesion.

Powder Coating vs. Traditional Painting: A Comparison

Comparing powder coating to traditional painting helps highlight the superior attributes of the former. While both methods can provide a visually appealing finish, it offers greater durability, impact resistance, and longevity. Traditional paint may require more frequent touch-ups and is generally more susceptible to damage from environmental factors. Additionally, powder coating’s solvent-free nature and minimal waste make it a more sustainable choice. When considering long-term performance and environmental impact, powder coating emerges as the more practical and eco-friendly option.

Tips for Selecting a Reliable Service

Choosing the right service provider is critical for achieving exceptional results. Look for a company with experience in your specific industry and a proven track record of delivering high-quality finishes. Request samples to assess the color, texture, and durability. Customer reviews and testimonials can offer insights into the service provider’s professionalism and customer satisfaction. Additionally, inquire about their facilities, equipment, and quality control processes to ensure they can handle your project with precision and care.

Conclusion

Powder coating is a remarkable finishing solution that combines durability, aesthetics, and environmental friendliness. By understanding the different finishes available, considering essential factors, and choosing the right type for your project, you can achieve a visually stunning and long-lasting coating. Whether you’re looking to protect a product from harsh conditions or elevate its appearance to new heights, powder coating offers a wide array of possibilities. Embrace this transformative coating process, and unlock the potential to bring your projects to a new level of excellence and endurance.