Every household relies on various appliances for daily comfort and convenience. From refrigerators to washing machines, these devices have become an integral part of our lives. So, when these devices fail, it’s a significant inconvenience. This is where repair technicians step in. These professionals have the skills and knowledge to diagnose, troubleshoot, and fix appliances, ensuring they run smoothly. But how does one become a skilled technician? The journey begins with appliance repair training.

As a beginner, your first step should be to explore appliance repair training or technical colleges that offer repair courses. This formal education can provide you with fundamental knowledge of devices, their components, and how they operate. Along with classroom learning, these programs usually involve practical labs, allowing you to gain hands-on experience in a controlled setting.

These courses typically cover a broad spectrum of appliances and their common problems, from refrigerators and air conditioners to laundry machines and stoves. Learning about different devices will enable you to become a versatile repair technician, ready to handle any appliance repair job.

Understanding Basic Components

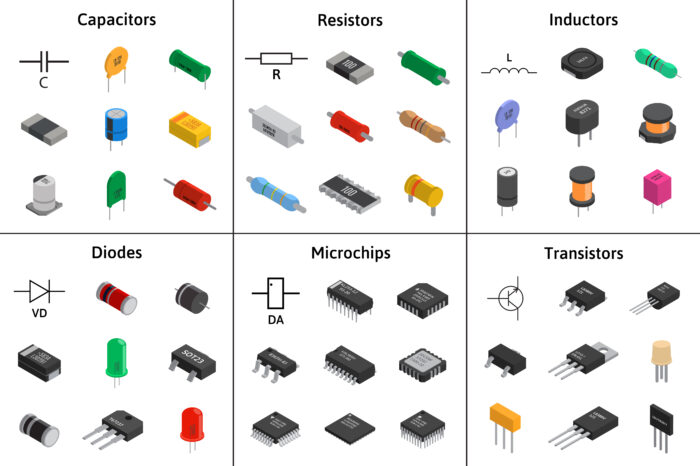

At their core, appliances are complex machines with numerous parts, including motors, switches, and thermostats. Different devices may have specific components, such as the compressor in a refrigerator or the heating element in an oven. Understanding how these parts interact and contribute to the overall functioning of the appliance is crucial for successful troubleshooting and repair.

In addition to these components, you should understand the basic principles of electricity, as most devices are powered by electrical energy. This includes knowledge about voltage, current, and resistance, as well as how to read wiring diagrams. These skills are necessary for diagnosing electrical problems in appliances and safely conducting repairs.

Essential Tools for Repair

In addition to theoretical knowledge, appliance repair training also involves mastering the use of various tools. These range from basic hand tools, like screwdrivers and wrenches, to more specialized equipment, like multimeters and circuit testers.

An essential tool in any repair technician’s kit is a multimeter. This device allows you to measure voltage, current, and resistance in an electrical circuit, which is invaluable for diagnosing electrical issues. A circuit tester is another important tool, used to detect whether a certain part of a circuit is powered.

You’ll also need tools for mechanical repair tasks. For instance, a set of screwdrivers of various sizes and types (flathead, Phillips, Torx, etc.) will help you disassemble and reassemble appliances. Pliers, wrenches, and hammers are also common tools used in repair.

Safety Precautions and Best Practices

Working with appliances involves certain risks, especially when dealing with electricity or gas. That’s why safety is a paramount concern in repair training.

One of the first things you’ll learn is to always disconnect the power before starting any repair. This reduces the risk of electric shock. You’ll also learn to wear personal protective equipment (PPE), such as gloves and safety goggles, to protect against potential hazards like sharp edges or flying debris.

If you’re working on a gas appliance, like a stove or a dryer, you’ll need to be particularly careful. These devices can be dangerous if not handled correctly, so training will cover how to safely disconnect and reconnect gas lines and how to detect gas leaks.

Troubleshooting Common Problems

Common issues you might encounter include appliances that won’t turn on, machines that don’t complete their cycles, and refrigerators that aren’t cooling properly. Each of these problems can have numerous potential causes, from a blown fuse to a faulty motor, so being able to correctly diagnose the issue is crucial.

Your training will teach you how to use a systematic approach to troubleshooting, starting with the simplest potential causes and moving to more complex possibilities. This method is both efficient and effective, helping you find the root cause of an issue without unnecessary work.

Diagnosing Faulty Parts and Components

Once you’ve identified the problem, the next step is to pinpoint the faulty part or component. This is where your knowledge of appliance components and your diagnostic tools come into play.

For example, if a dryer isn’t heating, the problem could lie in several components: the heating element, the thermostat, or the timer. Using your multimeter, you can test each of these components for continuity to identify which one is faulty.

Once the faulty component is identified, it’s time to determine whether it can be repaired or needs to be replaced. In some cases, a part can be fixed with a simple adjustment or cleaning. Other times, you’ll need to replace it entirely. Your training will teach you how to make this determination, and how to carry out the necessary repairs or replacements safely and effectively.

Repairing Electrical Devices

Electrical devices like refrigerators, dishwashers, and ovens are some of the most common ones you’ll encounter as a repair technician. These machines are complex and can present a variety of problems, so being able to effectively repair them is a crucial skill.

Your training will teach you about the specific components of these appliances and how they interact. For example, in a refrigerator, you’ll need to understand the operation of the compressor, the defrost system, and the temperature controls.

You’ll also learn about common problems with these devices and how to fix them. This might include replacing a faulty thermostat in a refrigerator, fixing a broken heating element in an oven, or replacing a worn-out motor in a dishwasher.

Repairing Mechanical Appliances

Mechanical appliances like washing machines and dryers involve a mix of electrical and mechanical components. As such, being able to repair these devices requires a broad range of skills.

Your training will include learning about the specific components of these machines, from the drive motor and transmission to the timers and switches. You’ll also learn how to diagnose common problems, such as a washer that won’t spin or a dryer that won’t heat.

One key aspect of working with these appliances is understanding how to disassemble and reassemble them. These machines can be complex, and a mistake in reassembly can lead to more problems down the line. Your training will give you the skills and confidence to take apart these machines, repair them, and put them back together correctly.

Handling Gas Appliances Safely

While many devices are electric, some, like stoves and dryers, can also run on gas. Working with these appliances requires special precautions due to the risk of gas leaks, which can cause fires or explosions.

Your training will cover how to work safely with gas appliances, including how to turn off the gas supply, disconnect and reconnect gas lines, and check for leaks once the repair is complete.

You’ll also learn about the specific components of gas appliances, like igniters and valves, and how to diagnose and fix common problems. This could include replacing a faulty igniter in a gas stove or fixing a blocked vent in a gas dryer.

Building a Successful Business

Finally, if you’re interested in starting your own appliance repair business, your training can provide valuable insights. You’ll learn about the essentials of running a business, from marketing and customer service to financial management and licensing requirements.

This knowledge can be crucial for success in the competitive repair industry. It’s not enough to just be good at fixing appliances – you also need to know how to attract and retain customers, manage your finances effectively, and comply with all relevant laws and regulations.

From your first introduction to appliance components to the advanced skills needed to run your own business, appliance repair training offers a comprehensive journey for anyone interested in this rewarding field. With dedication, practice, and the right training, you can go from beginner to pro and start a successful career in appliance repair.