Beauty manufacturing has become a booming industry with the rise of custom beauty products. As consumers demand more personalized and unique products, the need for custom beauty manufacturing has increased. But how exactly does it work behind the scenes? In this article, we’ll explore the process of custom beauty manufacturing, from concept to finished product.

The Conceptualization Stage

The conceptualization stage is the crucial first step in custom beauty manufacturing. It’s where the brand or individual comes up with the idea for their custom beauty product. This stage involves market research and identifying a gap in the market, as well as determining the unique selling point of the product. It’s also where the brand or individual decides on the target audience and sets the budget for the project. The conceptualization stage lays the foundation for the rest of the custom beauty manufacturing process, and it’s essential to get it right in order to create a successful, customized beauty product.

The Formulation Stage

Once the concept has been established, the formulation stage begins. This is where the custom beauty manufacturer develops the formula for the product. They take into account the ingredients requested by the brand or individual, as well as any specific requirements such as vegan, cruelty-free, or organic. The manufacturer may also conduct stability and compatibility tests to ensure that the product will be safe and effective.

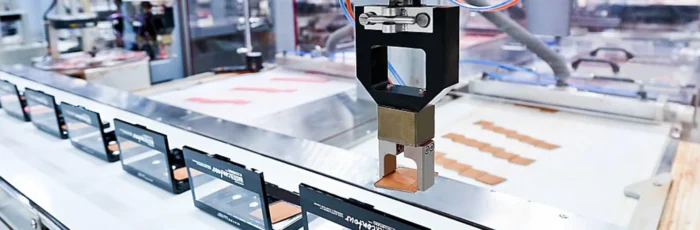

The Manufacturing Stage

Once the formula has been finalized, the actual manufacturing stage can begin. The custom beauty manufacturer will typically have a range of production capabilities, from small batches to large-scale production. They will also have the ability to fill and package the product according to the brand’s specifications.

Quality Control Stage

The quality control stage is a critical part of custom beauty manufacturing. It ensures that the product meets all necessary standards, such as FDA regulations and customer expectations. During this stage, the product is thoroughly tested for stability, consistency, and effectiveness. The custom beauty manufacturer will also check the product’s packaging and labeling to make sure that it’s accurate and meets the brand’s specifications. Any issues that are found during the quality control stage are addressed before the product is packaged and shipped. This ensures that the customer receives a high-quality, safe, and effective product that meets their expectations and is consistent with the brand’s image.

Packaging and Shipping Stage

Once the product has passed quality control, it’s time for packaging and shipping. Custom beauty manufacturers can offer a range of packaging options, including jars, tubes, bottles, and more. They can also apply labels and branding to the packaging to ensure that the product is fully customized to the brand’s specifications. The finished product is then shipped to the brand or individual, ready to be sold or used.

Conclusion

In conclusion, custom beauty manufacturing is a complex process that involves several stages, from conceptualization to the finished product. By working with a custom beauty manufacturer, brands and individuals can create unique, personalized beauty products that meet their specific needs and requirements. With the increasing demand for customization in the beauty industry, custom beauty manufacturing is poised to continue its growth and innovation in the years to come.