Carbon fiber is well known for being used in cars throughout the world. They are good as working car parts and as a covering for the car. It offers various benefits that can enhance the performance of your car to the maximum. While it’s such excellent material, it has various aspects that need to be explained.

From making carbon fiber to its use to its impact, it has various benefits and a few disadvantages. Read below to know about them in detail.

How Is Carbon Fiber Made?

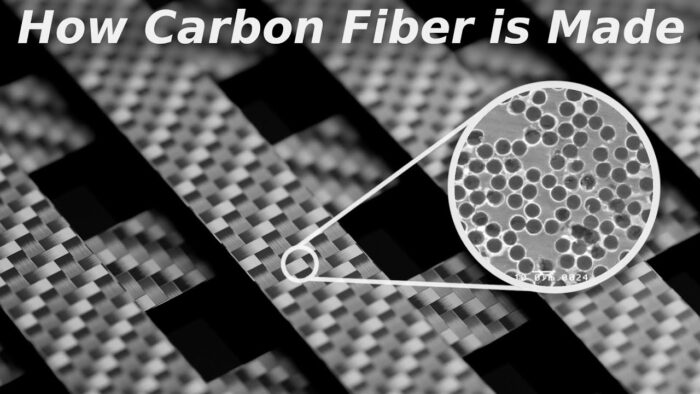

The making process of carbon fiber is very extensive and a great deal of attention is paid when it’s made. It’s an organic polymer with a major carbon component in its molecular structure. The process of making up strands of carbon fiber involves putting the polymer in high heat without oxygen. When the thin strands are formed they are twisted for a yarn-like structure.

The yarn-like strands of carbon fiber are woven into a thin layer of fabric. This layer is used as it is or combined with other layers to form a thicker layer for coating purposes. It is mixed with different materials like epoxy and molded into the shape of the part needed To form different parts of this fabric. Carbon fiber can also be used by mixing it with other materials to form a composite material that can be easily degraded.

One way carbon fiber fabric is widely used is as a carbon fiber car trim, where a major portion of the car is covered with carbon fiber to provide it protection against environmental materials. Other areas where carbon fiber composite parts are used are in aircraft, ships, spacecraft, racing cars, golf shafts, bicycles, fishing rods, etc. There is no end to the use of carbon fiber due to its characteristic property of being strong, lightweight, flexible and corrosion resistant at the same time.

Why Opt for Carbon Fiber for Your Car?

A car has two types of parts that are the internal parts and the external parts. The internal parts are those which solely work to run the car, and the external parts are those that one can look at without opening the car. Be it internal or external parts, carbon fiber is an excellent choice for the same and has never disappointed people. Read below in detail about why you should opt for carbon fiber for your car parts.

High Rigidity

The strands of carbon fiber are woven tightly together, because of which there is hardly any space in between. It is this factor that contributes to the high rigidity of carbon fiber. The process of making the yarn and fabric of the carbon fiber is so extensive and intricate that the resulting structure is very strong. Because of this strength, it’s used in cars, aircraft and ships for strong parts.

Flexibility in Products

Once the carbon fiber strands have been formed, they can be used as it is or made into a yarn and then used or made into a fabric or mixed with some other material and used however needed. There are multiple ways to make objects out of carbon fiber, and it doesn’t restrict the person from making only a particular object. Also, the strands and the fabric is so flexible that they can be easily folded or stretched to work however needed.

High Thermal Resistance

Due to its high rigidity, the whole structure of the carbon fiber fabric is highly stable. It promotes the temperature resistance of the fiber along with low thermal expansion and fatigue strength. In other words, it would neither expand nor contract when under high temperature and would not break midway. When used in cars, it can also enhance the safety of the car and the passengers.

Lightweight in Nature

Carbon is already lightweight and when it’s transformed into fiber the thickness of the final product can be controlled. Here the final product’s weight can go from being super lightweight if it’s extremely thin to considerably lightweight if it’s very thick. All over, it remains lighter than other metals in the automobile field as its basic feature is to be lightweight.

Absorbs Impact Energy

As the structure of carbon fiber is extremely lightweight and flexible, the lattice structure of the fiber is good at absorbing shocks. To a great extent, it can absorb the impact head-on, save the car from experiencing high damage, and increase the safety of the cars and passengers. Carbon fiber is extremely good at absorbing energy because of which it doesn’t expand when heated and can absorb sudden impacts well.

Impact of Carbon Fiber on the Economy

Carbon fiber has proved to be one of a kind material that has positively impacted the economy for the coming years. Its lightweight and flexibility have enabled automobiles to run faster than normal, which will significantly reduce oil consumption in the future. At the current pace due to lesser competition in the market, the price of carbon fiber is high. But with the expected return on investment in this field, many people have recently entered this field.

While it has significant advantages, there is only one disadvantage: there is no mass production of carbon fiber. That is, it is not biodegradable, and because a major portion of the waste of carbon fiber is produced in factories, this issue is concerning. Many people have started mixing carbon fiber with different materials to make it biodegradable, which has been successful to an extent. While there is still research left on this topic, the newer versions are regularly being checked to mass-produce biodegradable carbon fiber.

Conclusion

Carbon fiber is like a hero material in the automobile industry. It has major advantages for which it is used in various areas like aircraft, cars, ships, etc. Even though it has multiple uses and advantages, it’s less seen because it’s expensive. Once the issue of non-biodegradability is removed, there are a huge number of people that want to set foot in this field.